Quick Overview

This case study highlights how Review Data Scraping from Cold Storage helped a leading grocery supply chain brand enhance product freshness, reduce spoilage, and strengthen customer trust. The client partnered with Product Data Scrape to Extract Cold Storage Grocery & Gourmet Food Data and convert scattered customer reviews into actionable insights.

Client Name / Industry: Confidential | Grocery & Cold Storage Logistics

Service / Duration: Review intelligence scraping | 6 months

Key Impact Metrics:

- 32% reduction in quality complaints, 28% improvement in storage compliance, 22% faster corrective actions across facilities.

The Client

The client is a large grocery distribution company operating multiple cold storage facilities across urban and semi-urban regions. With growing competition from quick commerce players and rising consumer expectations, the cold chain industry is under intense pressure to deliver consistent quality, freshness, and transparency.

Market trends revealed that customers increasingly voice dissatisfaction through online platforms, apps, and supplier portals. However, the client relied on manual feedback collection and internal audits, which provided delayed and incomplete insights. This gap made Cold Storage customer review data scraping a critical requirement for transformation.

Before partnering with Product Data Scrape, the client faced fragmented data sources, inconsistent reporting formats, and limited visibility into facility-specific performance. Customer complaints related to temperature variance, delayed dispatch, and packaging damage were difficult to trace back to exact storage locations. Decision-making was reactive rather than proactive.

By integrating our Web Data Intelligence API, the client aimed to centralize review intelligence, gain real-time visibility into cold storage performance, and create a data-driven feedback loop that could support operational excellence, supplier accountability, and long-term quality assurance.

Goals & Objectives

The primary goal was to transform unstructured customer and partner reviews into structured intelligence that could directly improve grocery product quality. The client sought scalable, fast, and accurate data extraction to support enterprise-level decision-making and operational optimization.

From a business perspective, the objective was to enhance customer satisfaction, reduce spoilage losses, and improve brand credibility across retail and B2B channels. Technically, the client aimed to automate review collection, integrate insights into existing dashboards, and enable near real-time analytics for faster interventions. Accurate Extract Cold Storage grocery ratings Data was essential to benchmark facility performance and supplier compliance. Additionally, building a reliable Grocery store dataset allowed cross-platform analysis of trends and recurring quality issues.

Improvement in average product quality ratings

Reduction in repeat complaints by storage facility

Faster turnaround time for corrective actions

Increased data accuracy across review sources

The Core Challenge

The client’s biggest challenge was the lack of structured visibility into customer sentiment related specifically to cold storage operations. Reviews were scattered across eCommerce platforms, logistics portals, and internal feedback systems, making it nearly impossible to connect quality complaints with operational root causes.

Operational bottlenecks included delayed issue identification, manual review analysis, and inconsistent data tagging. Quality teams spent excessive time sorting feedback instead of acting on it. This inefficiency directly impacted data accuracy and response speed, especially during peak demand cycles.

Moreover, the absence of a centralized consumer review dataset For Cold Storage meant that recurring issues—such as temperature deviations or delayed stock rotation—went unnoticed until they escalated into large-scale complaints. The lack of historical review intelligence further limited trend analysis and predictive quality control.

Without automation, the client struggled to scale insights across facilities, leading to uneven performance and missed opportunities to proactively improve grocery product quality.

Our Solution

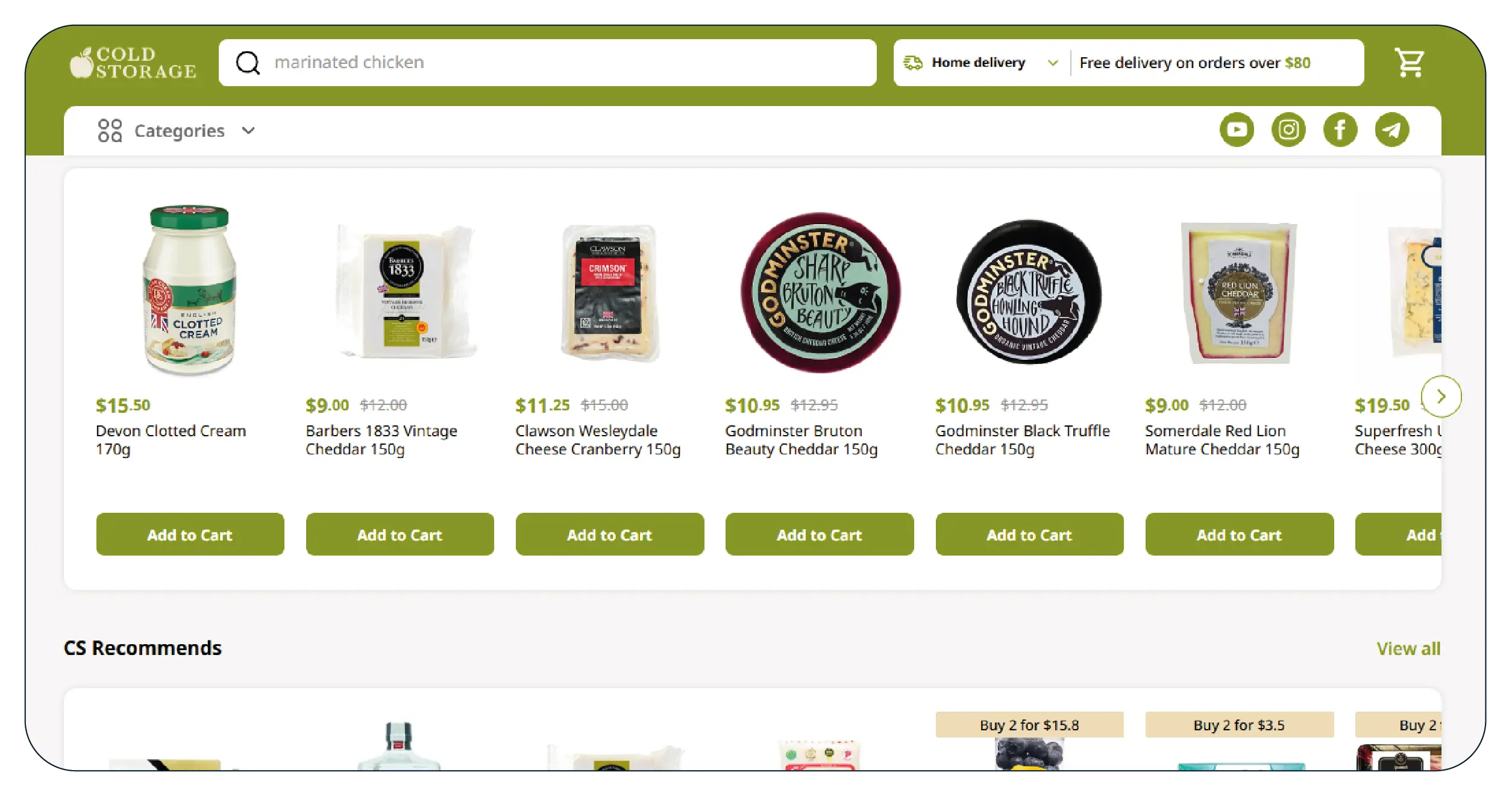

Product Data Scrape implemented a phased, technology-driven solution tailored to the client’s cold storage ecosystem. The first phase focused on identifying all relevant review sources, including marketplaces, logistics feedback platforms, and supplier review portals. This ensured complete coverage of customer sentiment tied to cold storage operations.

In the second phase, we deployed automated scraping workflows powered by intelligent parsers and data normalization frameworks. Reviews were extracted, cleaned, and categorized based on parameters such as storage conditions, delivery timelines, packaging quality, and freshness indicators. Our system also integrated a Real-time Cold Storage pricing scraper to correlate pricing fluctuations with perceived quality issues.

The third phase involved data enrichment and analytics integration. Sentiment analysis, keyword clustering, and facility-level tagging enabled the client to pinpoint underperforming storage units instantly. Insights were delivered through customizable dashboards compatible with existing ERP and quality management systems.

Each phase directly addressed a key challenge—automation replaced manual analysis, real-time alerts replaced delayed reporting, and structured intelligence replaced fragmented feedback. The result was a scalable, resilient review intelligence system that empowered the client to move from reactive issue handling to proactive quality assurance.

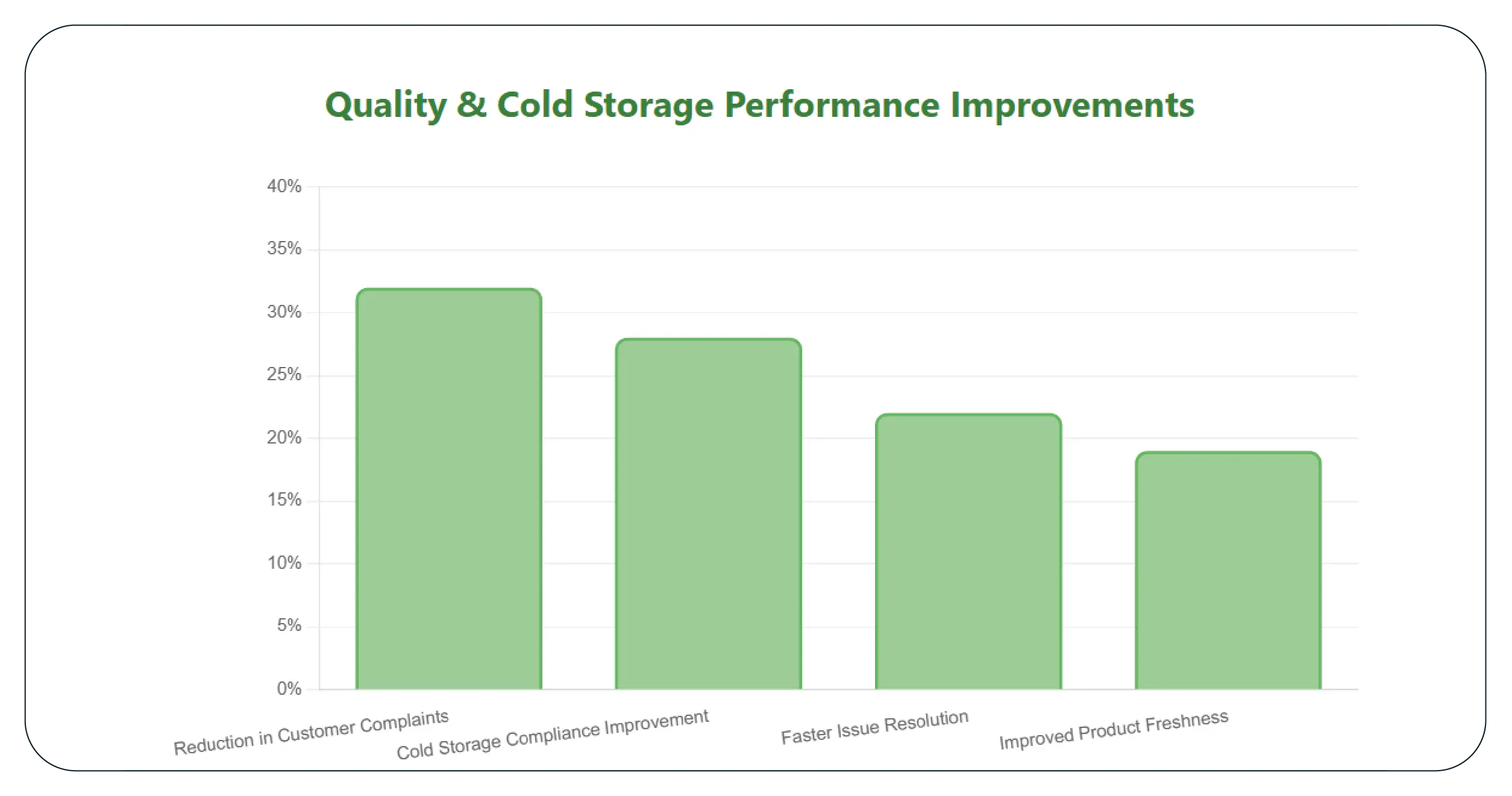

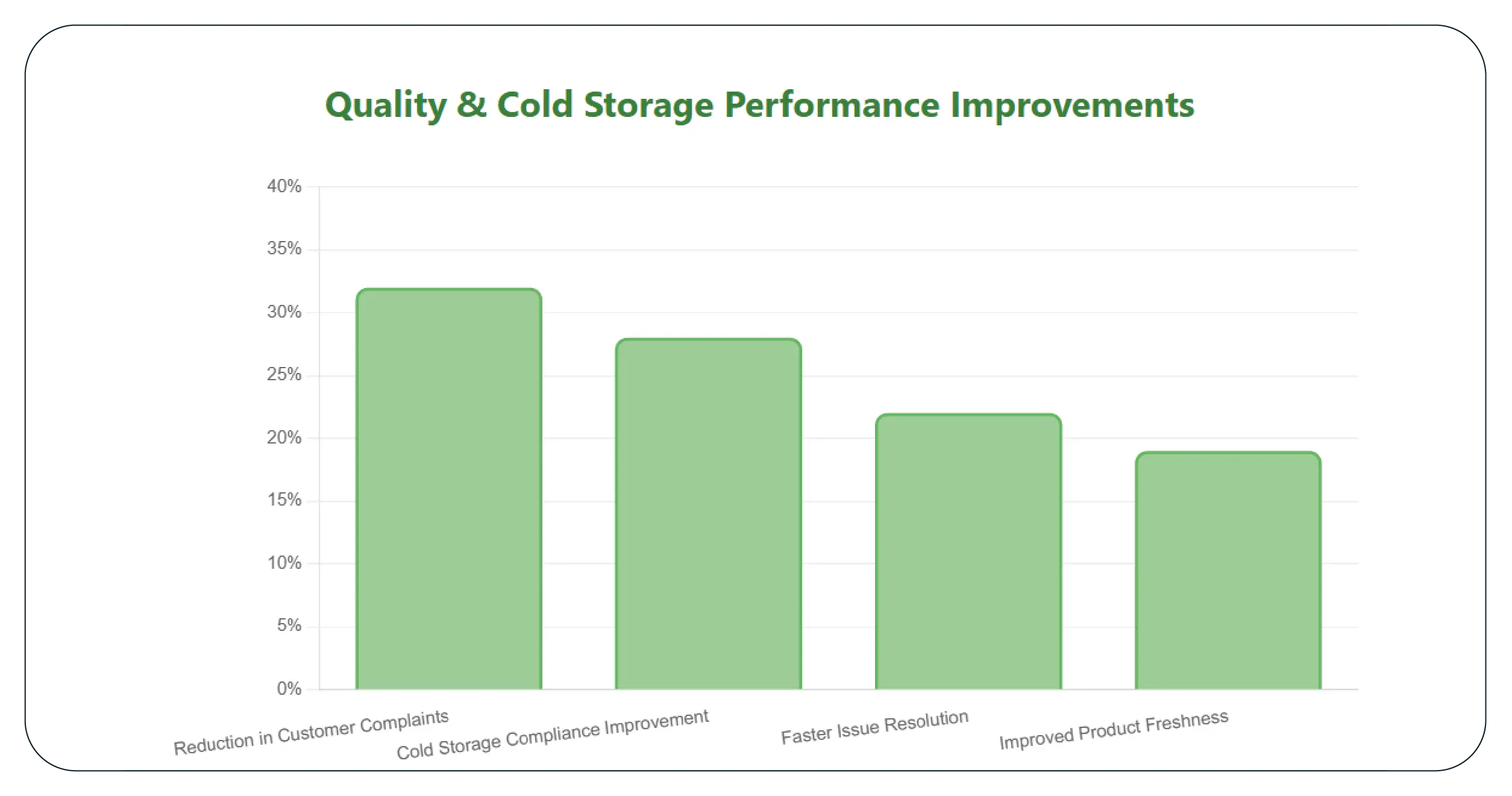

Results & Key Metrics

32% reduction in quality-related customer complaints

28% improvement in cold storage compliance scores

22% faster resolution of storage-related issues

19% improvement in average product freshness ratings

Enhanced visibility through Scrape Cold Storage grocery inventory Data

Results Narrative

With structured review intelligence in place, the client gained unprecedented clarity into cold storage performance. Teams could instantly identify problem areas, correlate complaints with inventory conditions, and take corrective action before issues escalated. The ability to analyze Scrape Cold Storage grocery inventory Data alongside reviews helped align stock rotation and storage practices with customer expectations. Overall, the solution delivered measurable improvements in product quality, operational efficiency, and customer trust.

What Made Product Data Scrape Different?

Product Data Scrape stood out through its focus on scalability, accuracy, and intelligence-driven automation. Unlike generic scraping tools, our proprietary frameworks delivered context-aware insights tailored to cold storage operations. Smart automation pipelines ensured minimal latency, while advanced tagging enabled facility-level performance tracking. The integration of a Cold Storage grocery availability Data API further enhanced visibility into stock readiness and freshness, giving the client a competitive edge in quality management.

Client’s Testimonial

“Product Data Scrape helped us unlock insights we didn’t even know existed. Their review intelligence solution transformed how we monitor cold storage quality. We now act on real-time feedback instead of reacting to complaints. The improvement in product freshness and customer satisfaction has been remarkable.”

— Head of Quality Assurance, Leading Grocery Distribution Company

Conclusion

This case study demonstrates how review intelligence can redefine grocery quality management. By turning unstructured feedback into actionable insights, Product Data Scrape enabled the client to strengthen cold storage performance and enhance consumer trust. As the grocery industry evolves toward faster deliveries and higher expectations, data-driven quality control becomes essential. Our expertise in Quick Commerce Grocery & FMCG Data Scraping positions brands to stay competitive, agile, and customer-centric in a rapidly changing market.

FAQs

1. Why is review data important for cold storage facilities?

Review data reveals real customer experiences related to freshness, handling, and storage quality, enabling proactive improvements.

2. What types of reviews are scraped?

We collect reviews from eCommerce platforms, logistics portals, supplier systems, and customer feedback channels.

3. How does scraping improve grocery product quality?

By identifying recurring issues early, brands can correct storage practices before quality degrades.

4. Is the data delivered in real time?

Yes, our automated pipelines support near real-time data extraction and analytics.

5. Can this solution scale across regions?

Absolutely. Our infrastructure is designed to scale across multiple facilities, platforms, and geographies.

.webp)